Increase Production Speeds with Triangle Cereal Packaging Solutions

Fill Different Types of Cereal at High Speeds with Triangle Vertical Form Fill Seal Baggers

Triangle X-Series vertical form fill seal (VFFS) baggers are a hygienic and efficient way to fill and seal bags of cereal at high speeds. Our X-Series VFFS bagging machines include three frame sizes and styles to best meet your application needs. With quick, tool-less changeover of sealing jaws or film rolls, all our bagging machine models are designed to run multiple package styles and sizes on the same machine. Enjoy less downtime and move more cereal out the door.

When it comes to sanitation, Triangle’s X-Series VFFS baggers are second to none. Customers love the open, accessible, easy to clean design. Available in three levels of sanitation, including stainless steel, stainless steel washdown, and USDA/3A models, with control box ratings from NEMA 12 to NEMA 4X.

Efficiently Place Bags of Cereal Into Boxes

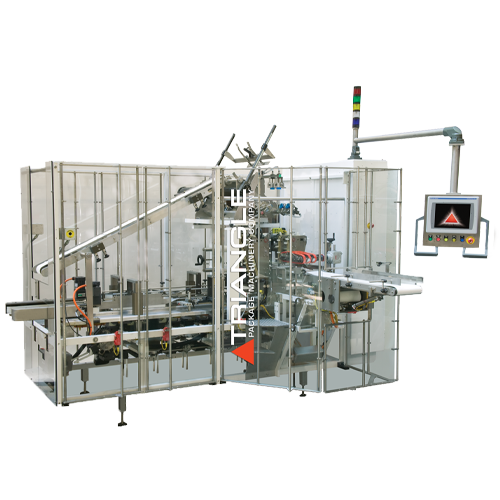

Pair an X-Series bagger with a bag-in-box cartoner for a complete cereal packaging system. With a Triangle bag-in-box system, you can easily achieve speeds of up to 100 cartons per minute–and all within a compact footprint. And, thanks to the ability for quick changeover, it can easily run multiple carton sizes.

Achieve Accuracy with Triangle Inline Scales

Triangle inline multihead weighers offer unique advantages for cereal packaging applications. Offering unmatched accuracy, these weighers feature vibration-resistant weigh cells and hand-detachable buckets. An optional dust enclosure ensures that powdered or sugary cereals stay within the system, and that contaminants stay out. Additional options include smooth or Rigid-tex finish to ensure even product flow. Pair the weigher with our X-Series VFFS machine for an integrated cereal packaging system run through a single HMI.

%20copy.png)

Easily Fill Pre-Made Pouches

Our pre-made pouch machine is an automated method for filling and sealing pre-made pouches of cereal. It is designed to fill and seal Doy bags, 3-sided seal, flat and Stand-Up Pouches (SUP), as well as zippered bags, at speeds up to 50 pouches per minute. Filling multiple types of cereal is simple with storage of up to 50 recipes that allows for quick and simple changeovers.