Fresh Produce Packaging Solutions

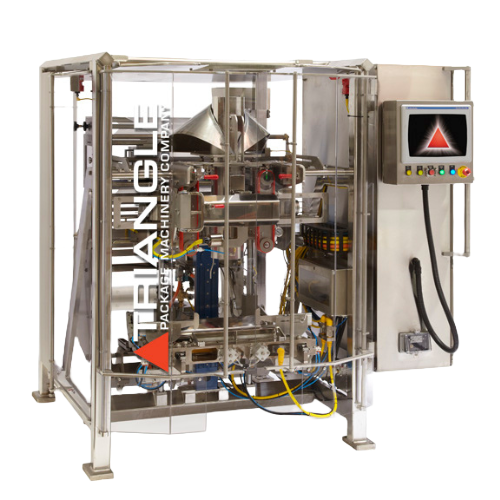

Delta Compact Sanitary Bagger

Designed with the fresh-cut produce market in mind but suitable for a variety of applications, this VFFS bagging machine includes a film cage designed to be as narrow as practical, yet can accommodate the 27.5-inch film roll needed to make 13-inch wide bags. When installed in a twin configuration, two compact baggers can fit on one salad line, 35 inches on center, to produce 120+ retail packages of leafy greens per minute! This also provides the flexibility to run varying film structures or film rolls, or to perform routine maintenance on one machine without disrupting production on the second machine. A pivoting HMI enables better accessibility and ease of use for a single operator. Even in a side-by-side configuration, the bagger’s small footprint is very similar in size to that of typical single tube baggers, allowing for significantly more production within the same footprint without having to add more feeding systems, labor and floor space run through a single HMI.

.png)

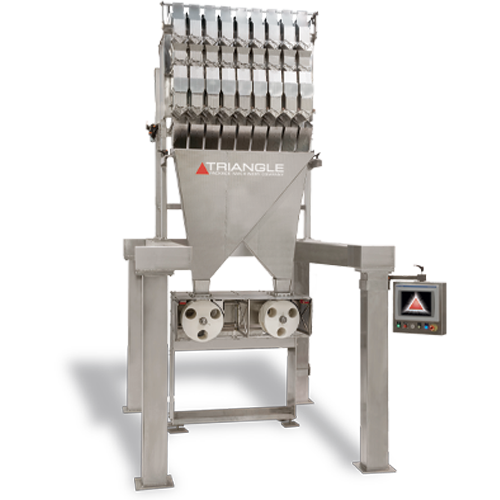

Rotary Depositing/Tray Loading Systems

Designed for tray/clamshell packaging applications, Triangle’s rotary depositor/tray loading system loads fresh cut or frozen produce into bowls, trays or partitioned sections at speeds up to 75 trays/minute for a single wheel produce packaging system and 150 trays/minute for a dual wheel produce packaging system.

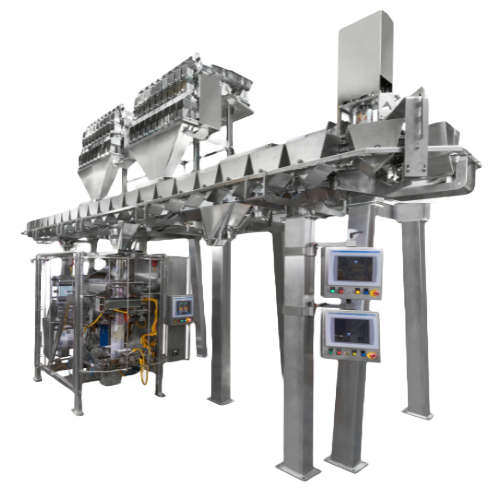

Product Blending System

Several product blending solutions are available for produce packaging applications with multiple ingredients. Choose from a single bagger and dual scale system or complete recipe blending system that combines multiple in-line multihead weighers, X-Series VFFS bagging machines, and a spout oval depositing system to produce a perfect blend of your products. In fact, we guarantee that each bag will contain every ingredient at a predetermined weight!

Pre-Made Pouch Filler

The Triangle/JDD rotary pouch filler is an automated method to fill and seal pre-made pouches. The rotary pouch filler is designed to fill and seal Doy bags, 3-sided seal, flat and Stand-Up Pouches (SUP), as well as zippered bags, at speeds up to 50 pouches per minute. Store up to 50 recipes for quick and simple changeovers.

X-Series VFFS Baggers

The X-Series is the faster, cleaner, smarter packaging solution. Unique features include:

Versatility

Available in intermittent or continuous motion models, the X-Series VFFS bagging machines include three frame sizes and styles to best meet your application needs. With quick, tool-less changeover of sealing jaws or film rolls, all of our bagging machine models are designed to run multiple package styles and sizes on the same machine. Changeover of forming tubes, film rolls, and sealing jaws is tool-less and quick, allowing fresh produce packagers to enjoy less downtime and move more product out the door.

Ultrasonic Technology

Triangle is the only North American company to not only offer Ultrasonic sealing, but to provide the flexibility to run Ultrasonic or traditional heat sealing on the same bagging machine. A unique, cold sealing technology, Ultrasonic sealing offers many benefits to fresh produce packagers, including improved OEE and reduced leakers, as well as labor, material and energy savings.

Sanitation

When it comes to sanitation, Triangle’s X-Series VFFS baggers are second to none. Customers love the open, accessible, easy to clean design. X-Series baggers are available in three levels of sanitation, including stainless steel, stainless steel washdown, and USDA/3A models, with control box ratings from Nema 12 to Nema 4X. In fact, Triangle offers the only vertical form fill seal bagger and forming tube designed to meet strict USDA and 3A sanitation standards.