Since 1923

Sanitary Vertical Form Fill Seal Baggers and More

Choose your Triangle Solution

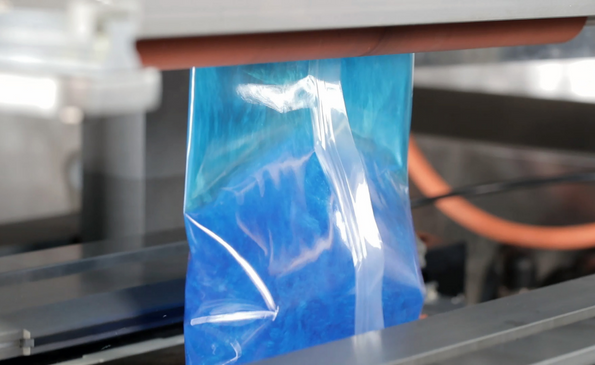

VFFS Bag Machines

Most versatile and sanitary VFFS baggers on the market. From powders to wet proteins to liquids. Proven performance in harsh environments. Smart IO technology, ultrasonic sealing, rotatable jaws and more.

Bag-in-Box Cartoners

Flexibility in a small footprint. Quick, auto-changeover from single to dual or quad packs in seconds. Pairs perfectly with a Triangle bagger and weigher combination. A unique belt infeed system protects your product.

Pre-Made Pouch Fillers

Simple, automated solution for filling and sealing pre-made pouches. Run Doy bags, 3-sided seal, flat and stand-up pouches (SUP) with ease. Simple integration with multihead weighers, augers or cup fillers.

Multihead Weighers

From cereal to wet proteins, and everything in between. Unmatched accuracy and speed. Even product distribution for optimal production. Mount directly on top of Triangle VFFS baggers. No mezzanines required.