Enhance Your Food Safety with Sanitary Packaging Machines for IQF

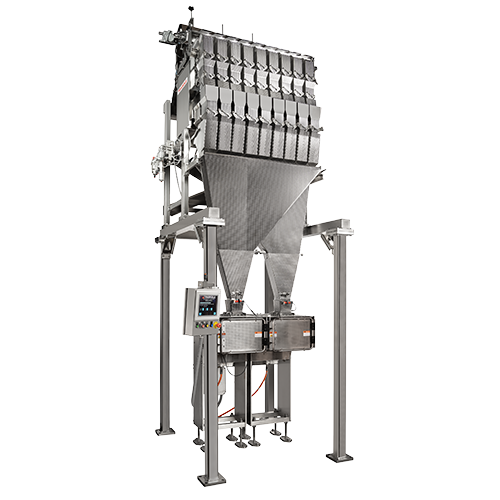

Reduce Product Giveaway with Inline Weighers for IQF

Triangle's inline weighers are ideal for high-speed frozen food packaging applications. Offering unmatched accuracy, our inline weighers feature vibration-resistant weigh cells and hand-detachable buckets. Available in smooth or Rigid-Tex finish to ensure even product flow. Multiple options such as adjustable feed trays (steep pitch to flat), rotating grater (to smooth product out and declump) and perforated trays (dewatering or fine removal). Pair the weigher with our X-Series VFFS machine for a seamlessly integrated IQF packaging system that can be run through a single HMI.

Increase IQF Packaging Yields with Rotary Wheel

If you need to fill trays or bowls with frozen foods or dinners, the Triangle rotary wheel can help you increase production yields. This system loads product into bowls, trays or partitioned sections at speeds up to 75 trays/minute for a single wheel tray packaging system and 150 trays/minute for a dual wheel tray packaging system. Pair with a Triangle inline weigher for a complete IQF packaging system.

Optimize Production with Automated Pre-Made Pouch Filling

Triangle's pre-made pouch machine is an automated method to fill and seal pre-made pouches. The pre-made pouch filler is designed to fill and seal Doy bags, 3-sided seal, flat and Stand-Up Pouches (SUP), as well as zippered bags, at speeds up to 50 pouches per minute. Store up to 50 recipes for quick and simple changeovers.

Vertical Form Fill Seal Baggers for IQF Keep Products Food-Safe

Triangle Delta intermittent motion and X-Series continuous motion vertical form fill seal baggers increase production yield while enhancing food safety efforts.

Built in the USA at our Chicago, IL facility and designed for 24/7 operation, Triangle baggers are rugged and run in even the harshest environments. They are also versatile IQF packaging solutions designed to meet your application’s needs–including reclosable packaging capabilties.