Increase Yields with Nuts & Snacks Packaging Solutions

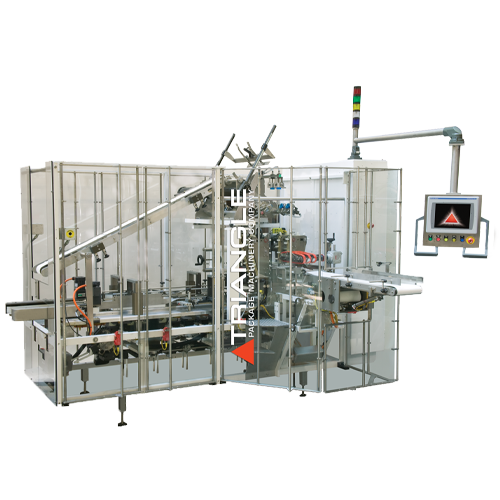

Achieve Fast Changeovers with VFFS Baggers

Efficient vertical form fill sealing is essential to your nuts and snacks packaging operations. Triangle VFFS baggers increase production efficiencies by allowing for quick changeover. An open, accessible design makes them easy to clean. Available in various levels of sanitation, including stainless steel, stainless steel washdown and USDA/3-A models.

For high-speed nut packaging applications, integrate a VFFS bagger with a high-speed cup filler from one of our preferred partners.

%20copy.png)

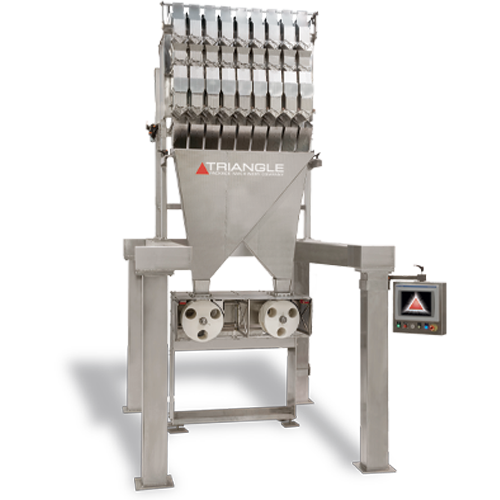

Save Floor Space with Inline Weighers

Triangle inline weighers are designed for the unique demands of nuts and snacks applications. Vibration-resistant weigh cells and hand-detachable buckets come standard. An optional dust enclosure is available for powdered or sugary products. Additional options include smooth or Rigid-Tex finish to ensure even product flow, as well as product blending systems.

Pair with a VFFS machine for an integrated snack packaging system that can be run through a single HMI. When you mount an inline weigher directly on top of a bagger, it saves you valuable floor space because no mezzanine is required.

Fill Trays and Bowls of Nuts and Snacks with a Rotary Wheel

Our rotary wheels are designed to fill trays or bowls of nuts and snacks at speeds up to 150 trays per minute. With a simple servo setting, speeds can change easily to match line speed. The tray loader provides precise targeted dumps into small bowls or trays with partitions and is ideal for hard-to-handle, odd-shaped nuts and snacks products.

Ramp Up Bag-in-Box Cartoning Speeds

If your snack packaging application requires you to put a bag in a box, Triangle has the cartoner for you. Our bag-in-box cartoners can achieve speeds up to 100 cartons per minute–all within a compact footprint. Reduce downtime with quick and simple changeover.

For a complete system, pair a VFFS bagger and inline multihead weigher with a bag-in-box machine, all controlled through a single control box with Rockwell Automation’s ControlLogix.

Easily Fill and Seal Pre-Made Pouches of Nuts and Snacks

Fill pre-made 3-sided seal and Doy bags with one of our pre-made pouch machines. Reach speeds of up to 60 pouches per minute. Store up to 50 recipes for quick and simple changeovers. Ideal for products such as crackers, cookies, granola, puffs, popcorn, dried fruit, nuts, beef jerky and more.

.png)