Increase Yields with Triangle’s Pasta Packaging Solutions

According to Statista, from 2023 to 2028, the pasta market is expected to grow annually by 6.97%. Triangle’s pasta packaging solutions are designed to meet the growing demands for and unique needs of your dry or IQF pasta products–keeping them food-safe and handling them gently enough to prevent broken or damaged products. From VFFS baggers and inline weighers to a rotary wheel and pre-made pouch machine, we have the right pasta packaging solution for you.

Achieve Flexibility on Your Line with a VFFS Bagger for Pasta

Our versatile vertical form fill seal (VFFS) baggers are available in three levels of sanitation to meet your needs, including stainless steel, stainless steel washdown and USDA/3-A. With a Triangle VFFS bagger for pasta, you can:

- Run multiple package styles and sizes on the same machine

- Achieve quick, tool-less changeover of forming tubes, film rolls and sealing jaws

- Easily access the machine for cleaning

%20copy.png)

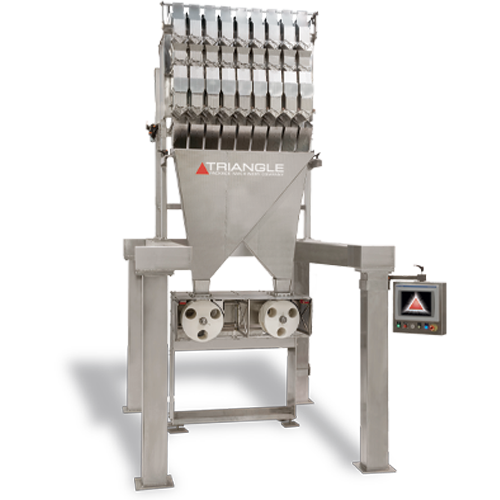

Ensure Even Product Flow with an Inline Weigher

For an integrated pasta packaging system that can be run through a single HMI, a Triangle inline multihead weigher can be paired with a Triangle VFFS bagger. These weighers with vibration-resistant weigh cells have quick, hand-removable features such as detachable buckets for easy accessibility and sanitation. Adjustable feed trays help provide even product flow, as do options like smooth or Rigid-tex finish.

Quickly Fill Pasta Meals or Dinners with Rotary Wheel

The Triangle rotary wheel machine loads fresh or IQF pasta into bowls, trays or partitioned sections. Fill at speeds up to 75 trays/minute for a single-wheel tray packaging system and or 150 trays/minute for a dual-wheel.

Automatically Fill and Seal Pre-Made Pouches with a Pasta Packaging Machine

When you need an automated method to fill and seal pre-made pouches of pasta, Triangle has the solution for you. Our pre-made pouch machine is designed to fill and seal Doy bags and 3-sided seal, at speeds up to 60 pouches per minute. Store up to 48 recipes for quick and simple changeovers.