Boost Productivity in a Small Footprint with a Compact Sanitary Bagger

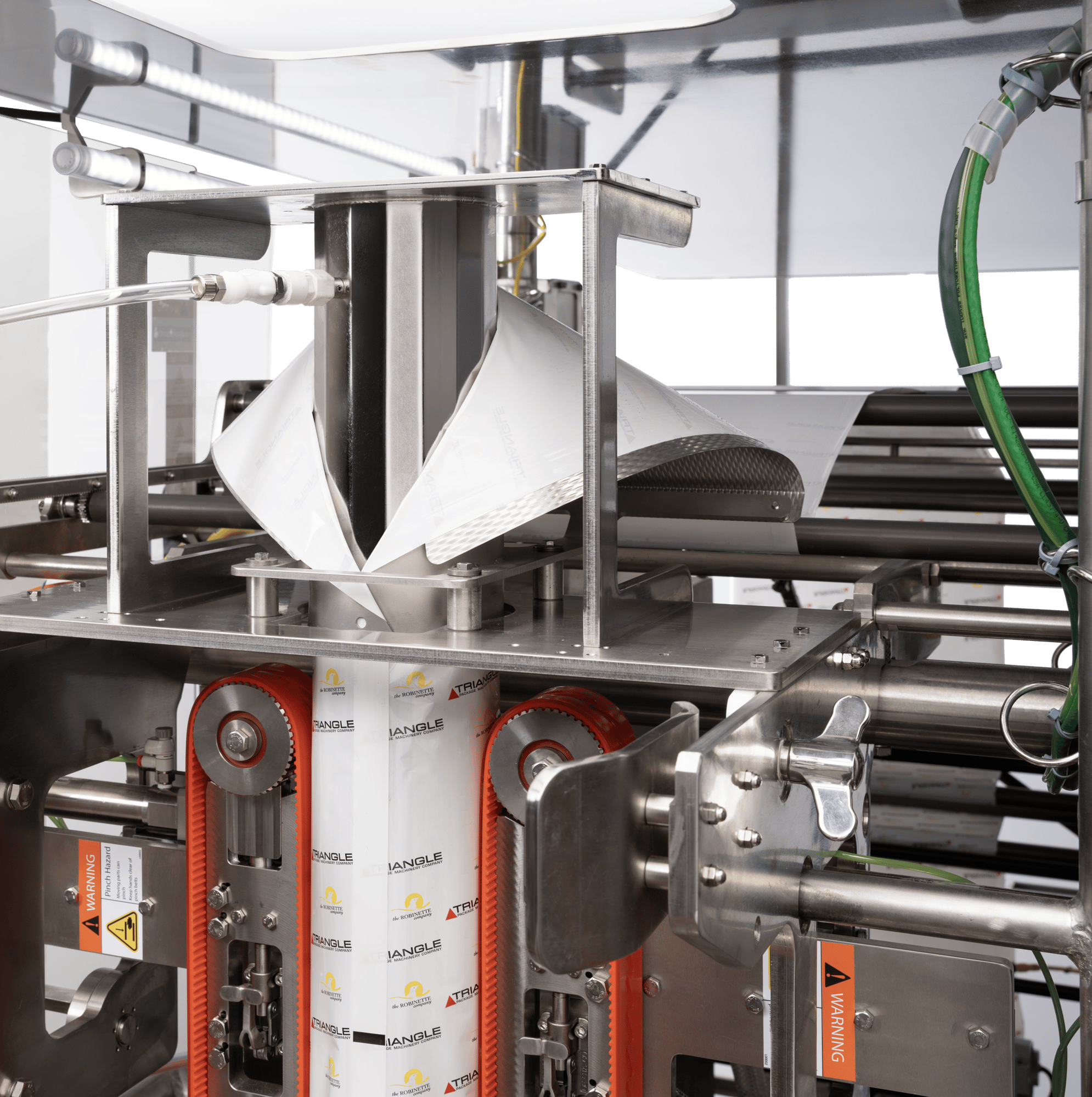

Originally designed for the produce market, the Triangle Compact Sanitary Bagger (CSB) helps food packagers and processors achieve optimized forming, filling and sealing yields within a small footprint.

The Triangle CSB features a user-friendly, easy-to-use bilingual HMI, and can run as a single unit or linked in a side-by-side twin configuration with a single scale – all within the footprint of a single traditional bagger while providing the ability to run each bagger independently.

Give Your Production the Versatility It Needs with a Small Footprint Vertical Bag Machine

The easy-to-use CSB is a small footprint vertical bag machine that is designed to be a flexible solution for your production needs. Features that add to this vertical form fill seal bagger’s versatility include:

- Packages a wide range of products, from leafy greens to proteins

- Runs a variety of bag sizes (from 2.5” to 13” wide and 15” long)

- Ability to manage two bag sizes at the same time in dual configuration

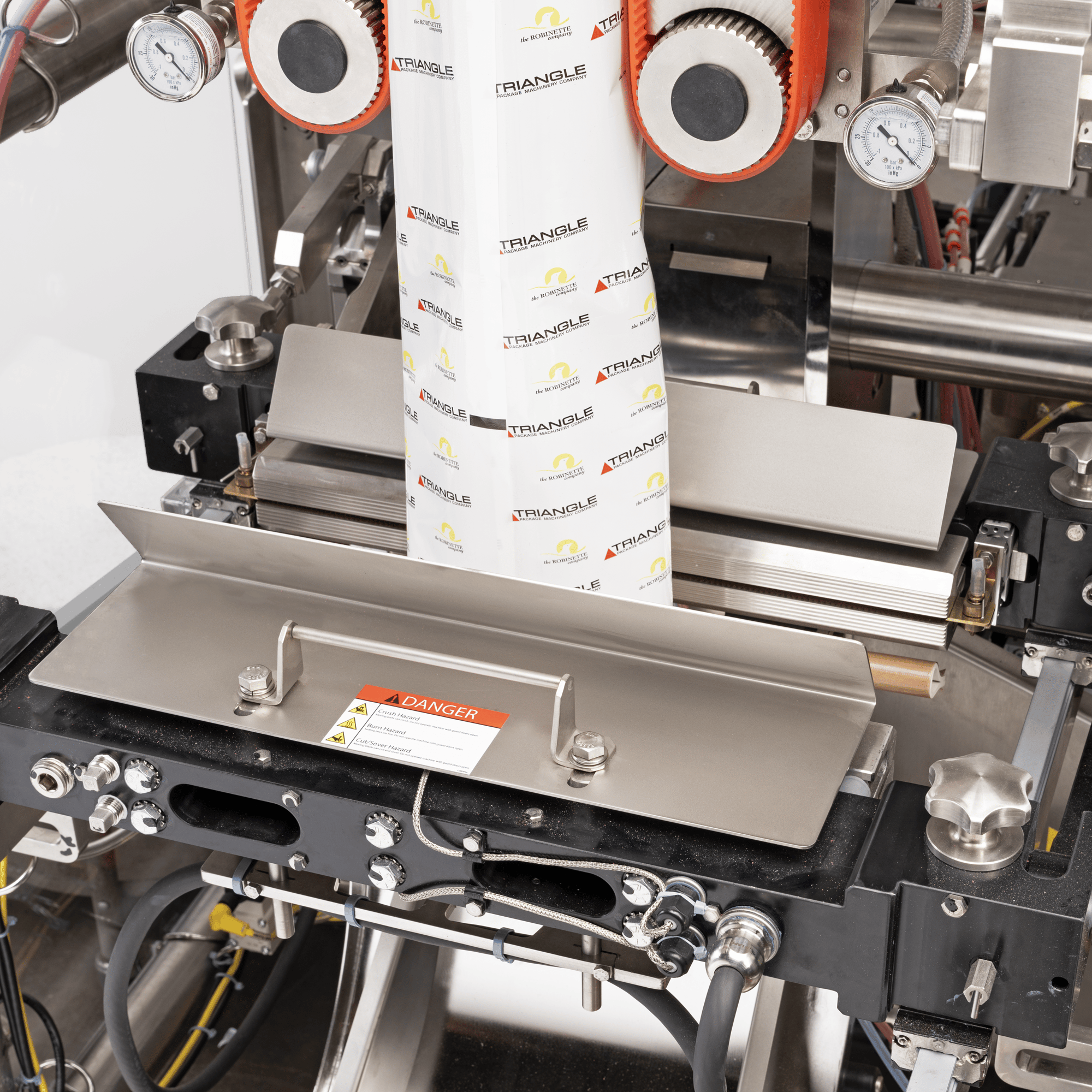

- Heat or ultrasonic sealing options to suit your product needs

- Quick change parts

Increase Output with a High-Speed, Compact Sanitary Bagger

These Compact Sanitary Baggers don't just fit in a small footprint – they are packed full of features and designed to perform at high speeds. While a single machine can run 100+ bags/minute, a pair of CSBs paired in our twin configuration can run 200+ bags/minute.

Featuring Triangle’s updated, intuitive HMI, the CSB can change recipes, bag specs and other ongoing adjustments in just minutes – adding to its ease of use and flexibility in any environment.

With connectivity via Ethernet communication, the Compact Sanitary bagger is able to provide high-speed, real-time feedback via IO-Link.

Additionally, in twin configuration, both baggers operate independently, so executing a changeover or maintenance on one machine will not impact productivity on its twin machine.

With two Compact Sanitary Baggers, you can do 2x as much as a single traditional bagger in the same footprint!

Fit Two Small Footprint Vertical Bag Machines in the Space of One Traditional Bagger

When you need a bagger, but don’t have a lot of space to work with, these small footprint vertical bag machines are a perfect solution. It is designed for dual configuration capabilities, allowing you to run two baggers side-by-side or use it as a single independent bagger to optimize your floorspace and production. With the ability to run the baggers independently, you can keep product moving and production flowing even when executing maintenance and changeovers.

Space-saving features of our small footprint vertical bag machines include:

- 36” center-to-center distance for scale discharges

- User-friendly pivoting HMI allows access to both screens from either side

- Internally mounted control box leaves extra room in aisleways

Enhance Food Safety with a Compact Sanitary Bagger

Keeping your product food-safe is your top priority, which is why the Compact Sanitary Bagger is designed with the consumer in mind. With state-of-the-art sanitation and washdown features, it is designed to meet strict sanitary requirements.

Sanitary design features of the Compact Sanitary Bagger include:

- Solid round bar stainless steel frame, fully welded and electropolished

- Film path covered by stainless steel top plate

- Ability to clean in place

- 3A-rated feet

- Open concept frame

- Internally mounted, pivoting control box for easy machine access

- Anodized and Teflon-coated aluminum jaws and heater bars

- Discharge height at 32” to allow for sanitary conveyors

- Optional 3-A rollers

Built and serviced in the USA at our Chicago, IL facility, the Compact Sanitary Bagger is backed by our 100+ years of experience.

Compact Sanitary Bagger Specifications

The Compact Sanitary Bagger is designed to easily integrate into your new or existing line while providing high-speed, sanitary forming, filling and sealing.

| Compact Sanitary Bagger Specifications: | |

| CSB | |

| Max Speed | Up to 100/min |

| Max Bag Width | 13" |

| Footprint | 36"W x 120"D |

| Control Box | NEMA 4X |

| Rating | IP69K Servos |

| PLC | Rockwell |

| Connection | Ethernet |

| Sealing Options | Heat or Ultrasonic |