Enhance Your Food Safety with Triangle Poultry Packaging Solutions

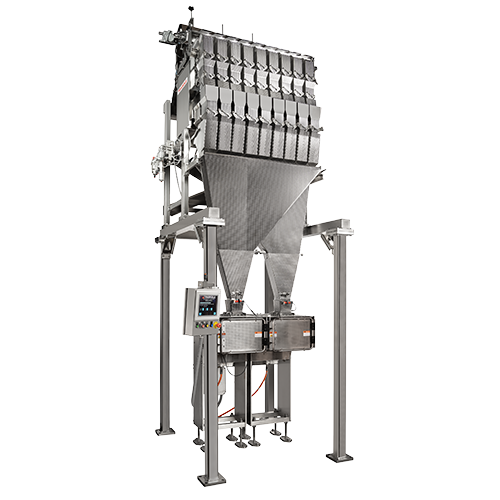

Ensure the Success of Your Line with a Belt-Fed Weigher & VFFS Bagger for Poultry

Triangle belt-fed weighers safely handle your wet, sticky poultry products. Pair one with a Triangle vertical form fill seal bagger for a complete poultry packaging solution. The scale mounts directly over your bagger, meaning there’s no mezzanine required. It’s never been easier to eliminate unnecessary sources of contamination, reduce your overhead costs, save floor space and further enhance your poultry packaging line’s food safety.

Ramp Up Poultry Packaging Yields with a Food-Safe Rotary Wheel

If you need to load poultry into TV dinners or frozen meals, the Triangle rotary wheel is an ideal solution. Designed for tray/clamshell packaging applications, this poultry packaging system loads fresh or frozen poultry into bowls, trays, or partitioned sections at speeds up to 75 trays/minute for a single-wheel poultry packaging system and 150 trays/minute for a dual-wheel.