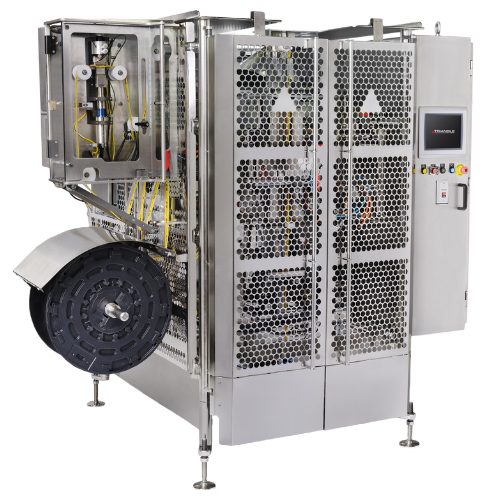

Sanitary Intermittent Motion VFFS Baggers

Delta Series vertical form fill seal baggers increase production yield while enhancing food safety efforts. Built and serviced in the USA at our Chicago, IL facility and designed for 24/7 operation, the Delta is rugged and built to last in even the harshest environments. With 360° machine access, maintenance and cleaning are made simple. Smart IO Technology improves troubleshooting and preventative maintenance efforts by proactively sensing changes such as air pressure fluctuation, when film rolls are running low and more.

VFFS Machines Reduce Downtime with Quick Changeovers

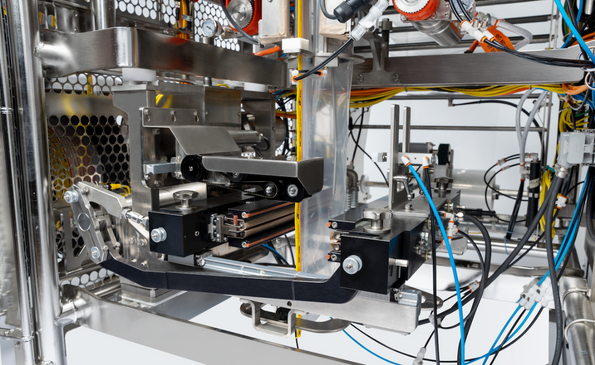

Complicated changeovers are time consuming and costly. The Delta Series of VFFS baggers offers quick and simple changeovers allowing end users to easily run multiple bag styles, including pillow, gusseted, flat bottom and EZ-stand bags. Centerlining allows for change parts to be either color-coded or alphanumeric. Tool-less, quick change parts that reduce downtime include:

- 16-sided forming tubes

- Film rolls

- Vertical back seals

- Sealing jaws

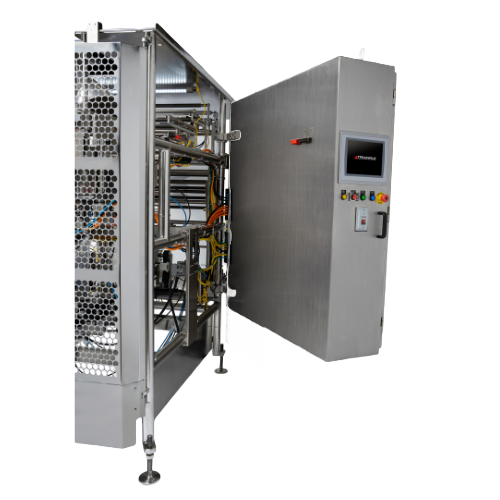

Sanitary Design Keeps Products Safe

Delta VFFS bag machines are designed and built with even the strictest sanitary requirements in mind. Available in three levels of sanitation including stainless steel, stainless steel washdown and USDA/3-A. Featuring round barstock frames and smooth, ground welds, harborage points are eliminated. Other sanitary features include:

- Sloped control box which pivots to provide 360° of machine access

- Servo motors available in three sanitation levels

- Open cable management

- 16-sided forming tube

- Optional stainless steel guard doors

Delta VFFS Specifications

The Delta VFFS bagger is designed to easily integrate into your new or existing line while providing high-speed, sanitary forming, filling and sealing.

| Delta Bagger Specifications: | |||

| Standard | Compact | Dual | |

| Max Speed | Up to 100/min | Up to 100/min | Up to 200/min |

| Minimum Bag Width | 3" | 2.25" | 2.25" |

| Max Bag Width | 15" | 13" | 13" |

| Footprint | 45"W x 42"D | 36"W x 120"D | 72"W x 120"D |

| Control Box | NEMA 4X | NEMA 4X | NEMA 4X |

| Rating | IP69K Servos | IP69K Servos | IP69K Servos |

| PLC | Rockwell | Rockwell | Rockwell |

| Connection | Ethernet | Ethernet | Ethernet |

| Sealing Options | Heat or Ultrasonic | Heat or Ultrasonic | Heat or Ultrasonic |

Delta VFFS Bagger Options

Compact/Dual Configuration

Run two baggers side-by-side in a compact footprint. Accepts dual discharge of single multihead weigher. Speeds up to 120+/minute.

Zipper Tape

Simply package bulky foods in easy access bags that fully open across entire width of package.

Rotatable Jaws

Easily switch from pillow to 3-side seal bags in under 10 minutes.

Multiple Bag Styles

Run multiple bag styles, including EZ-stand, pillow bags, gusseted and flat bottom bags.